Sulfur Coated Urea SCU

Sulfur Coated Urea SCU

| Product Name: | Sulfur Coated Urea SCU |

| CAS No.: | 57-13-6 |

| Formula: | CH4n2o |

| EINECS: | 200-315-5 |

| Appearance: | Granular |

| Density: | 1.32 g/m3 |

| Customization: | Available |

| Place of Origin : | Shangdong,China |

| MOQ : | 10T (Sample free) |

| Certificate: | ISO 22241-1, DIN 70070 standards |

Sulfur Coated Urea SCU Description

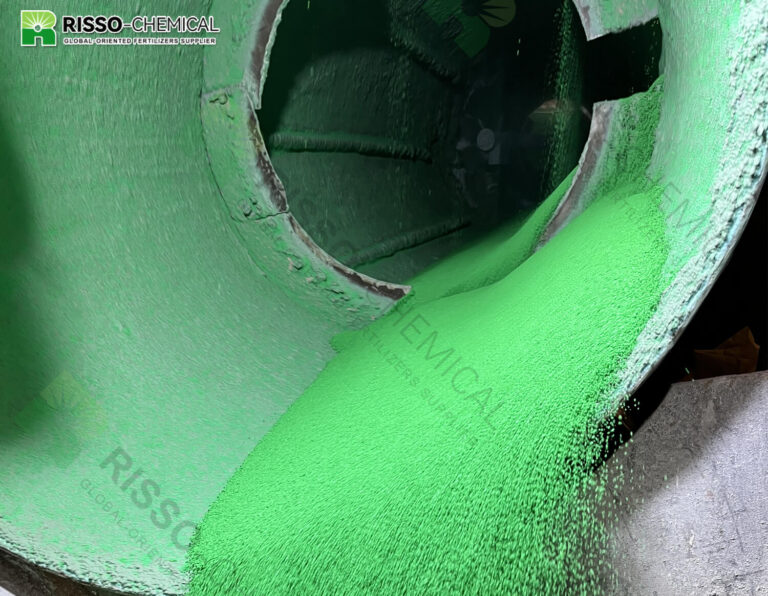

Sulfur as the main wrapping material, wrapped urea, to achieve slow release of nitrogen fertilizer, also known as sulfur-coated urea. The wrapping material has sulfur or microcrystalline wax, according to the different coating materials, it can be divided into sulfur-coated controlled release fertilizer and resin-coated controlled release fertilizer and other fertilizers.

Sulfur-coated urea has a unique color, belongs to the inorganic coating type of slow-release fertilizer, urea or compound fertilizer surface has a layer of film, the unique sulfur composition, can control the rate of nutrient release, nutrient release continuous and stable, suitable for a variety of soils and crops, to meet the nutritional needs of the crops due to the seasons, to improve the quality and increase yields. Urea or compound fertilizer has a film on the surface, unique sulfur composition, can control the rate of nutrient release.

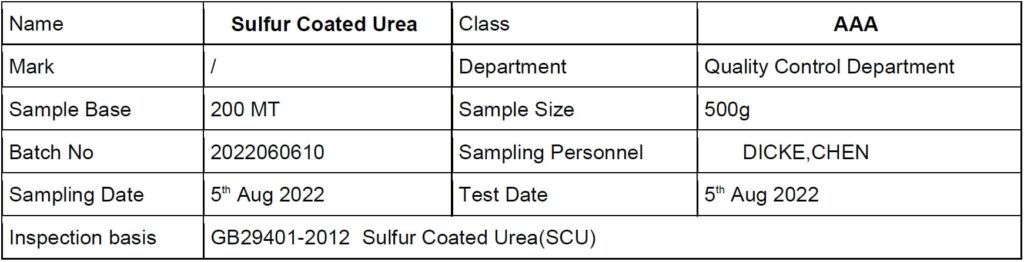

Sulfur Coated Urea Specifications

Packaging & Shipping

How does Risso ensure the quality of urea fertilizers?

1. Before production: Risso will set up a strict production plan, determine the quality of urea and process requirements, provide the necessary resources for the process and determine the key production processes (production equipment, key process points, key quality requirements of the process products) to establish self-inspection and mutual inspection between teams.

2. During the production process: we keep in communication with customers at any time, we can provide customers with videos or photos of the urea production process, to ensure that customers have no worries.

3 . Before delivery: Before shipment, we will ask the third party organization to issue the test report of urea fertilizer according to the requirements specified by customers.

What will you get when touch?

✔ Tailored solutions for your project.

✔ One-stop product, tech, market

Sulfur Coated Urea Scu: Guide

In spring and summer, the temperature rises, rainfall is abundant, when the crop grows vigorously, the amount of fertilizer. The microporous membrane warming, soil moisture into the membrane, melting part of the fertilizer, liquid fertilizer nutrients from the membrane microporous outflow into the soil, for crop growth needs. When a drought occurs, the soil is short of water, the fertilizer is difficult to release from the capsule in the form of liquid nutrients, avoiding the crop is burned due to excessive nutrients.

When the temperature drops, crops grow more slowly and need less fertilizer, at which time the micropores of the capsule become smaller and nutrient release is reduced accordingly, avoiding nutrient waste.

Compared with ordinary fertilizer, the utilization rate of fertilizer is improved. It can be said that the nutrient release law of controlled release fertilizer and crop fertilizer law is consistent, so it is also known as “intelligent controlled release fertilizer”.