Let more growers get greater benefits

Korean Clients Visit Risso Fertilizer Factory

- Company News

- September 12, 2025

- 6:04 pm

On Sep 10, a three-member procurement and technical delegation from Korea visited Risso Fertilizer in Shandong, China, for a two-day technical and business visit. The delegation aimed to gain detailed insights into Risso’s NPK compound fertilizer production system and the newly commissioned Polymer Coated Urea (PCU) production line, including laboratory float tests on bulk-sampled products.

List of Contents

Day 1: Compound Fertilizer Production Hall & Warehouse

Delayed Evening Tour Due to Safety Inspection

Arrival & Schedule Adjustment

The Korean delegation arrived in Tai’an at around 16:00. At the time, senior management was conducting a safety inspection of the factory. To ensure safety and production order, the factory arranged the tour after the inspection was completed.Tour Highlights

Raw Material Weighing & Automated Blending: Demonstrated automated formula systems ensuring precise NPK ratios.

Mixing & Granulation: Explained key parameters of wet/dry mixing and drum granulation processes.

Drying, Screening & Packaging Logistics: Showcased intelligent packaging, automated palletizing, moisture protection, and FIFO warehouse management.

The delegation highly appreciated Risso’s strict adherence to production safety, quality management, and warehouse traceability systems.

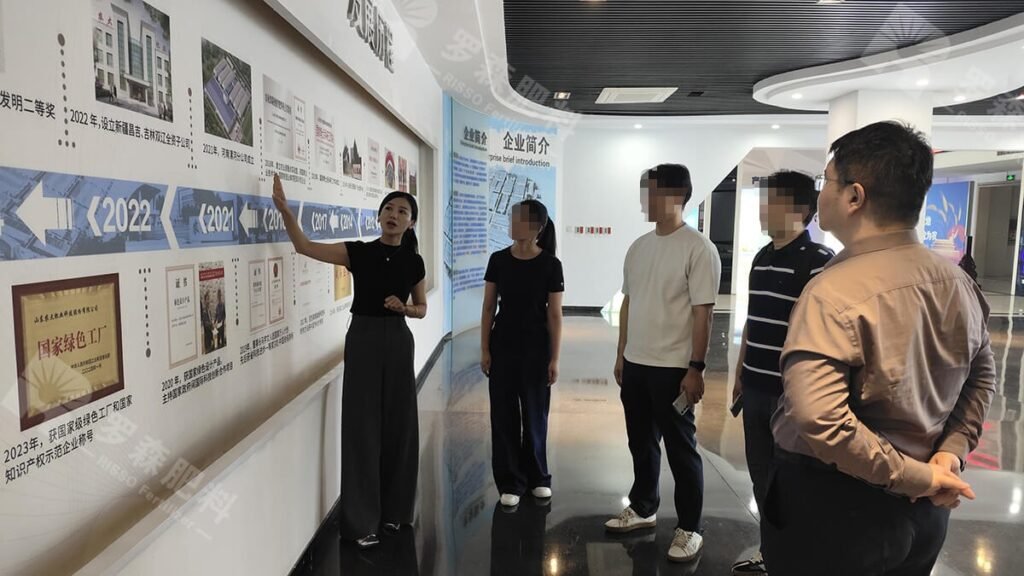

Day 2: Resin Coated Urea Production Line

The second-day focus was on Risso’s newly built Polymer Coated Urea (PCU) production line. The technical team provided detailed demonstrations of:

Automated Production Equipment

Including pre-heating granulation, resin coating, drying & curing, and online quality inspection systems, highlighting efficient and stable production.Online Quality Control

Real-time monitoring of coating thickness, nitrogen content, and release curves ensures consistent controlled-release performance.

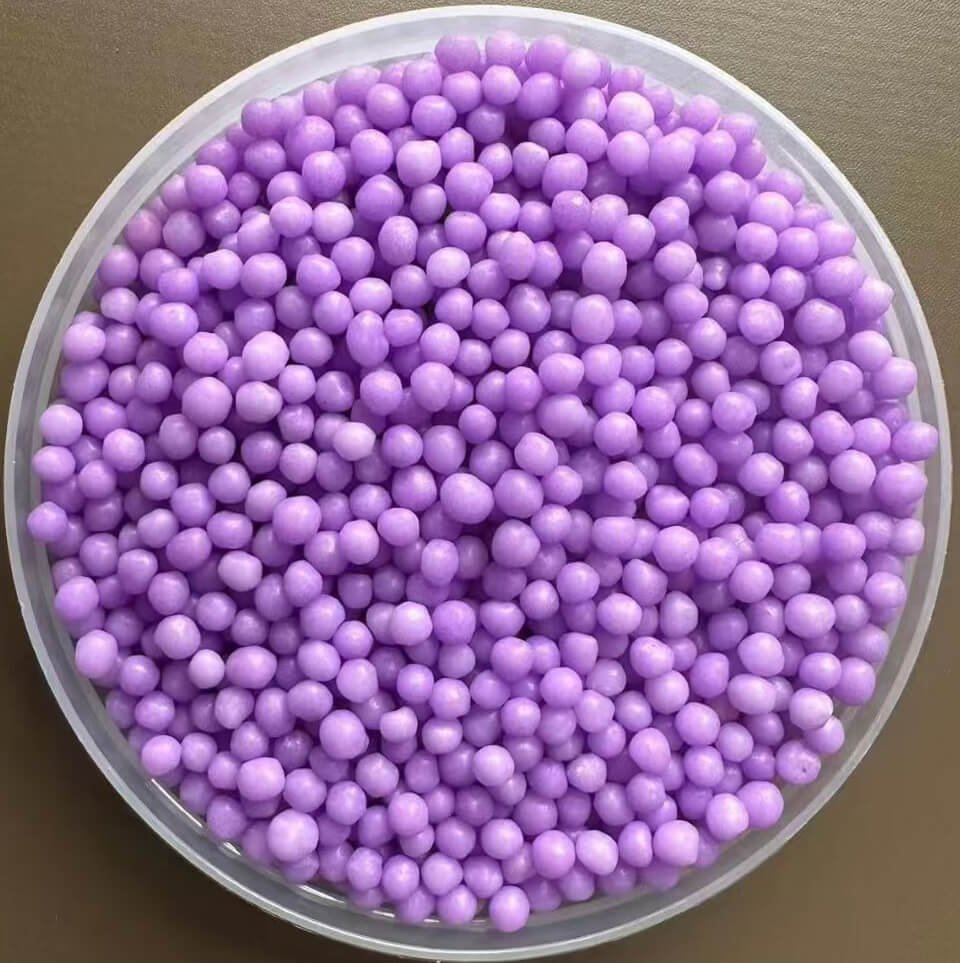

Laboratory Float Test

To verify PCU’s performance in shallow water applications such as paddy fields, the delegation observed laboratory float tests:

Testing Method: Small samples were taken from bulk product and placed in lab water tanks to observe sedimentation speed and depth.

Results: The resin-coated urea pellets were uniform and sufficiently dense, fully sinking within minutes, demonstrating excellent anti-floating performance suitable for Korean paddy cultivation.

The three-member delegation expressed high appreciation for both the test results and the production line automation, and showed strong interest in further field trials and long-term supply cooperation.

Polymer Coated Urea (PCU)) Technology Highlights

Precision Release: Multi-layer resin coatings enable customizable release cycles ranging from 30 to 120 days, adaptable to various crops.

Durable Coating: Resistant to mechanical damage, suitable for long-distance transport and diverse fertilizer application equipment.

Environmental Benefits: Reduces nitrogen volatilization and leaching, improves fertilizer efficiency, and complies with Korean and international environmental standards.

Business Discussions & Cooperation Prospects

Risso and the Korean delegation discussed market requirements, customized formulations, and long-term supply. The delegation highlighted Risso PCU’s anti-floating, long-release, and automated production capabilities and confirmed plans to proceed with field trials and procurement cooperation.

Conclusion: Risso’s Ongoing Innovation

This visit not only confirmed the safety, reliability, and high quality of Risso’s compound fertilizer and PCU products, but also demonstrated the company’s leading position in controlled-release fertilizer technology, intelligent production, and quality management systems. Risso will continue to innovate, providing high-efficiency and environmentally friendly fertilizer solutions for global agriculture.

Related Fertilizers

- Article

What will you get when touch?

✔ Quick & helpful reply within 6 hours.

✔ Tailored solutions for your project.

✔ One-stop product, tech, market

TRENDING

Want to find a China fertilizer manufacturer?

Risso will be your best choice; send us your request for your fertilizer details requirement.

TAIAN RISSO CHEMICAL FERTILIZER CO.,LTD

- Address: High-tech Development Zone, Taian City, Shandong Province

© Copyright 2017 RISSO CHEMICAL. All Rights Reserved.