Let more growers get greater benefits

How is NPK fertilizer manufactured?

- Industry News

- September 19, 2018

- 10:35 am

The Manufacturing Process of NPK Fertilizer: A Professional Overview

NPK fertilizers, containing nitrogen (N), phosphorus (P), and potassium (K), are fundamental to modern agriculture, playing a critical role in optimizing crop yield and soil fertility. Understanding the intricate manufacturing process of NPK fertilizers is essential for agricultural professionals, as it informs decisions about nutrient management and sustainable practices.

In this blog, we’ll take a comprehensive look at how NPK fertilizers are manufactured, covering every step in detail from raw material sourcing to final packaging.

List of Contents

1. Prepare raw materials for NPK production

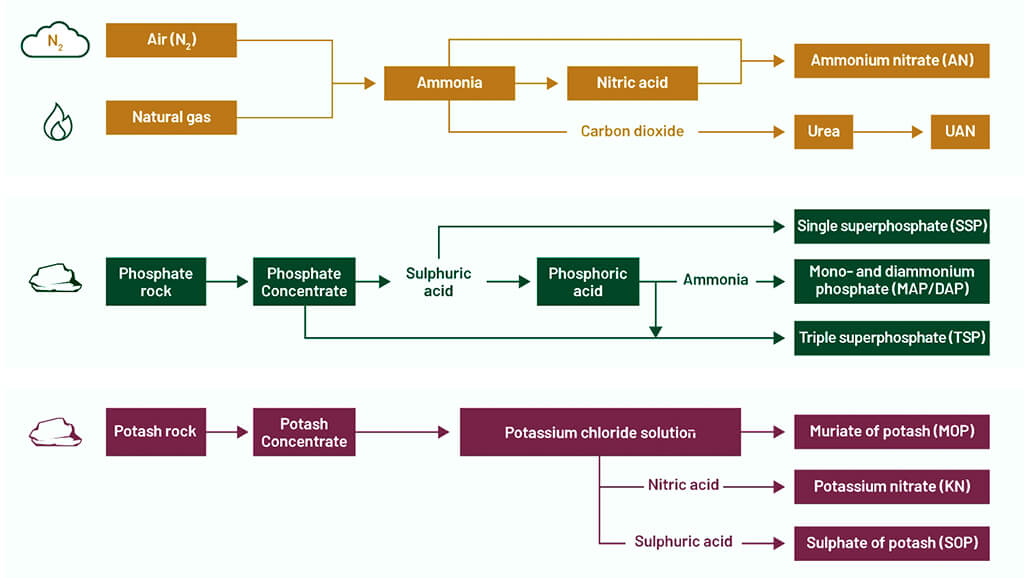

Nitrogen (N) Production

The nitrogen component in NPK fertilizers is typically derived from ammonia (NH3), which is produced through the Haber-Bosch process. This industrial process converts atmospheric nitrogen (N2) into ammonia using the following steps:

- Reaction: Nitrogen gas is reacted with hydrogen (sourced from natural gas or water electrolysis) at high temperatures (around 450–500°C) and pressures (150–200 atm) in the presence of an iron-based catalyst.

N2(g)+3H2 (g)→2NH3(g)

- Ammonia Recovery: The resulting ammonia gas is condensed into liquid ammonia by cooling it under pressure.

Ammonia is a key ingredient in various nitrogen fertilizers such as urea (CO(NH2)2), ammonium nitrate (NH4NO3), and ammonium sulfate ((NH4)2SO4), all of which may be incorporated into NPK blends.

Phosphorus (P) Production

Phosphorus in NPK fertilizers is usually derived from phosphate rock, which is rich in calcium phosphate (Ca3(PO4)2). The process of converting phosphate rock into usable phosphorus involves:

- Mining: Phosphate rock is extracted from deposits, which are typically located in countries like Morocco, China, and the U.S.

- Wet Process for Phosphoric Acid: The phosphate rock is ground into a fine powder and treated with sulfuric acid (H2SO4), producing phosphoric acid (H3PO4) and calcium sulfate (gypsum).

Ca3 (PO4) 2+3H2SO4 →2H3PO4 +3CaSO4

- Phosphoric Acid Purification: The phosphoric acid produced can then be concentrated and purified for use in fertilizers. Phosphoric acid is typically combined with ammonia to form ammonium phosphate (MAP or DAP), which can be blended into NPK formulations.

Potassium (K) Production

The potassium in NPK fertilizers is sourced from potash, a term referring to potassium-containing salts such as potassium chloride (KCl). The extraction of potash involves:

- Conventional Mining: Potash is extracted from underground deposits using traditional mining techniques or solution mining, where water is injected into the deposit, dissolving the potash and pumping it to the surface for recovery.

- Purification: The mined potash is then purified to remove impurities like sodium and magnesium salts, yielding a high-purity potassium chloride that can be used in fertilizers.

Potassium sulfate (K2SO4) and potassium nitrate (KNO3) are also used as sources of potassium, especially in chloride-sensitive crops.

2. Nutrient Formulation

The nutrient formulation process involves blending nitrogen, phosphorus, and potassium in precise ratios to meet the agronomic needs of different crops. Manufacturers develop custom NPK formulations based on:

Crop Type: Different crops require different nutrient ratios. For example, leafy vegetables may require higher nitrogen content, while fruit-bearing crops need more phosphorus and potassium.

Soil Conditions: Soil testing helps determine the nutrient deficiencies in the soil, guiding the NPK ratio required for optimal growth.

Common formulations include:

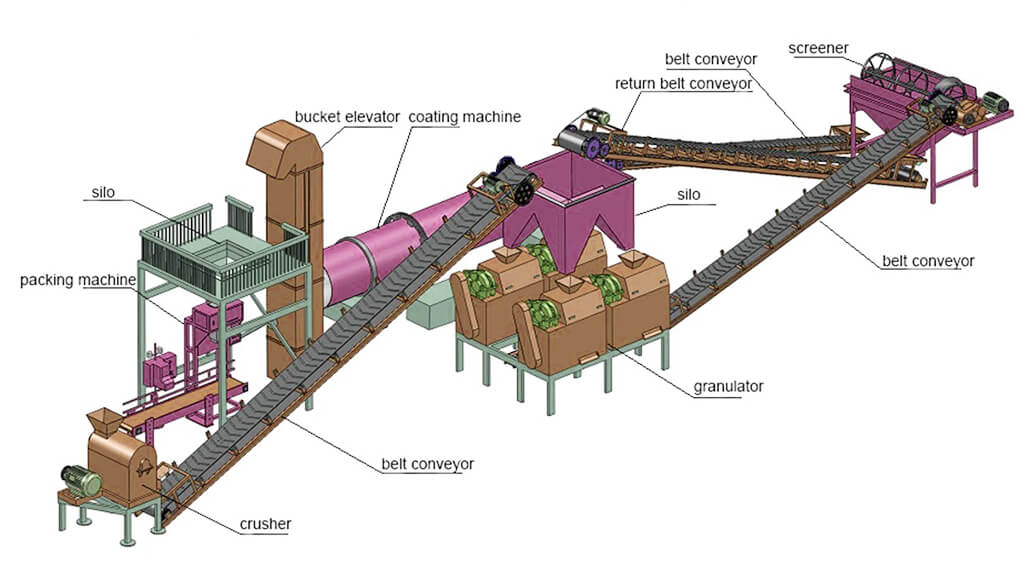

3. Mixing and Granulation

Raw Material Preparation

After preparing the raw materials (Diammonium Phosphate, urea, potash, etc.) are sourced, they are prepared for blending. Each component must be ground to a fine powder or mixed in slurry form to ensure proper integration.

Blending

In the blending stage, raw materials are combined in the specified NPK ratio. This can be done using either dry blending or slurry mixing:

- Dry Blending: The powdered or granulated forms of the nutrients are mechanically mixed in precise proportions. This method is simple but requires the components to be well-matched in particle size to ensure even distribution during application.

- Slurry Mixing: In cases where wet granulation is used, the ingredients are dissolved or suspended in a liquid, forming a slurry. This allows for a more homogeneous mixture and facilitates the formation of granules during the next step.

Granulation

Granulation is a critical phase in NPK manufacturing, as it converts the mixture into granules that are easier to handle and apply. Granulation can be carried out using one of several methods:

- Pan Granulation: A rotating pan or disc is used to roll the fertilizer mixture into spherical granules, with water or a binder added to aid in granule formation.

- Drum Granulation: The mixture is placed in a rotating drum where it is tumbled, causing particles to stick together and form granules.

- Tower Granulation Process:It is a widely used method in fertilizer production, particularly for NPK fertilizers. In this process, a slurry of raw materials is sprayed from the top of a tall tower. As the slurry falls through the tower, it cools and solidifies into spherical granules.

The granulation process also enhances the fertilizer’s physical characteristics, improving its flowability and reducing dust generation.

4. Drying and Cooling

After granulation, the fertilizer granules contain moisture that must be removed to ensure product stability. This is achieved by passing the granules through rotary dryers, where hot air reduces the moisture content to an optimal level (typically below 5%).

Following drying, the granules are cooled using air or cooling drums to prevent moisture re-absorption and hardening of the granules. Proper cooling ensures the granules retain their shape and do not clump together.

5. Screening and Coating

Once dried and cooled, the granules undergo screening to separate oversized and undersized particles. The screened material is recycled back into the granulation process, while the appropriately sized granules move on to further treatment.

To enhance the performance of the fertilizer, some manufacturers apply coatings to the granules. Coatings may include:

- Anti-caking agents: Prevent granules from sticking together during storage.

- Slow-release coatings: Enable gradual nutrient release, reducing the need for frequent applications and minimizing nutrient loss to the environment.

6. Quality Control

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the final product meets industry standards and specifications. Quality checks typically include:

- Nutrient Analysis: Ensures that the NPK content matches the specified formulation.

- Moisture Content: Moisture levels are controlled to prevent caking and ensure long shelf life.

- Particle Size Distribution: Ensures uniformity of granules for consistent application.

- Contaminant Testing: Ensures that heavy metals and other impurities are within acceptable limits.

7. Packaging and Distribution

Once the fertilizer has passed all quality control checks, it is packaged into bags or bulk containers for distribution. Packaging may vary depending on market demands and the application requirements of the end-user. Automated bagging systems are used to fill, seal, and label each bag, ensuring that the product is properly identified with information such as:

- NPK ratio

- Weight

- Application instructions

- Safety warnings

The product is then shipped to distributors or directly to agricultural operations for application.

Environmental Considerations

The NPK fertilizer manufacturing process, while crucial for global agriculture, poses several environmental challenges. These include:

- Greenhouse Gas Emissions: The production of ammonia for nitrogen fertilizers is energy-intensive and a significant source of CO2 emissions.

- Nutrient Runoff: Excessive fertilizer application can lead to nutrient runoff into water bodies, causing eutrophication and water quality degradation.

To mitigate these impacts, fertilizer manufacturers are increasingly adopting sustainable practices, such as:

- Renewable Energy: Utilizing renewable energy sources to power production facilities.

- Controlled-Release Fertilizers: Reducing nutrient loss and environmental impact by developing slow-release and polymer-coated fertilizers.

- Recycling By-products: Using waste products from other industrial processes in fertilizer production.

Conclusion

The manufacturing of NPK fertilizers is a highly technical process that involves careful control of raw materials, chemical reactions, and environmental factors. From sourcing raw nutrients to granulating and packaging the final product, each step requires precision to ensure the fertilizer’s efficacy and sustainability. As the agricultural industry faces growing challenges, the evolution of more efficient and environmentally friendly fertilizer production methods will be critical in meeting global food demands responsibly.

Understanding the detailed manufacturing process helps agricultural professionals make informed decisions, optimizing fertilizer use for improved crop yields while minimizing environmental impacts.

Risso Fertilizers cordially invites partners and professionals to visit our NPK production facility for business discussions and collaboration. Our advanced facility upholds the highest standards in NPK fertilizer production, designed to meet the evolving needs of modern agriculture. We look forward to building strong, mutually beneficial partnerships and driving innovation for sustainable agricultural growth.

Fertilizer Related Products

If you want to know other questions about Production of NPK fertilizer or NPK fertilizers , please contact us and we will provide professional answers.

- Article

What will you get when touch?

✔ Quick & helpful reply within 6 hours.

✔ Tailored solutions for your project.

✔ One-stop product, tech, market

TRENDING

Want to find a China fertilizer manufacturer?

Risso will be your best choice; send us your request for your fertilizer details requirement

TAIAN RISSO CHEMICAL FERTILIZER CO.,LTD.

- Address: High-tech Development Zone, Taian City, Shandong Province

© Copyright 2017 RISSO CHEMICAL. All Rights Reserved.